- CORPORATE

-

PRODOTTI

- MICROPILE AND ANCHOR RIGS

- LARGE DIAMETER PILES

- GEOTECHNICAL

- Macchine multifunzione

- Macchine per pozzi

- Esplorazioni minerarie

- CERCHI UNA MACCHINA USATA?

- DOWNLOAD

- SERVIZI

- RETE VENDITA

- NEWS

- CONTATTI

Compila il form per avere tutte le risposte che stai cercando.

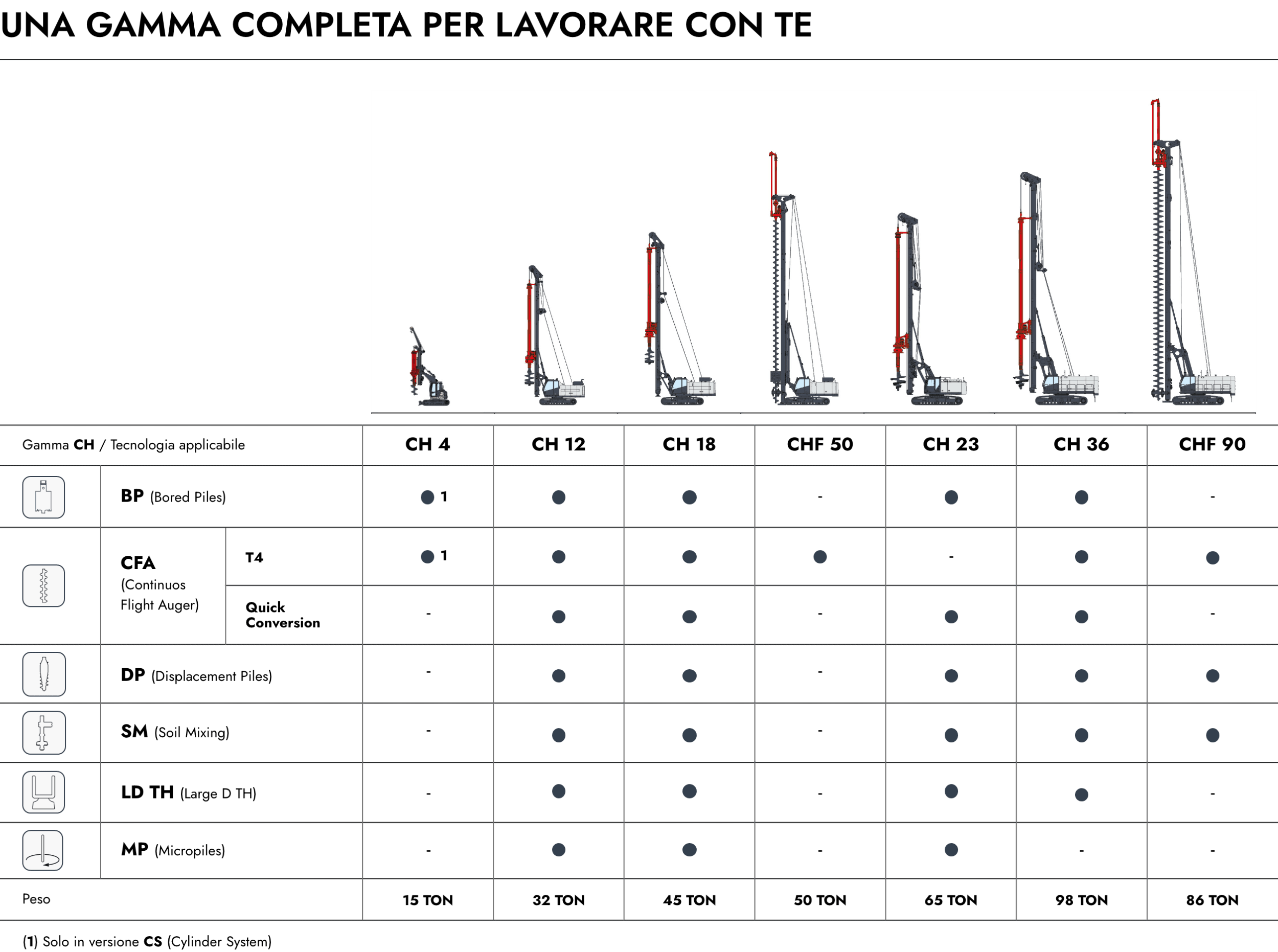

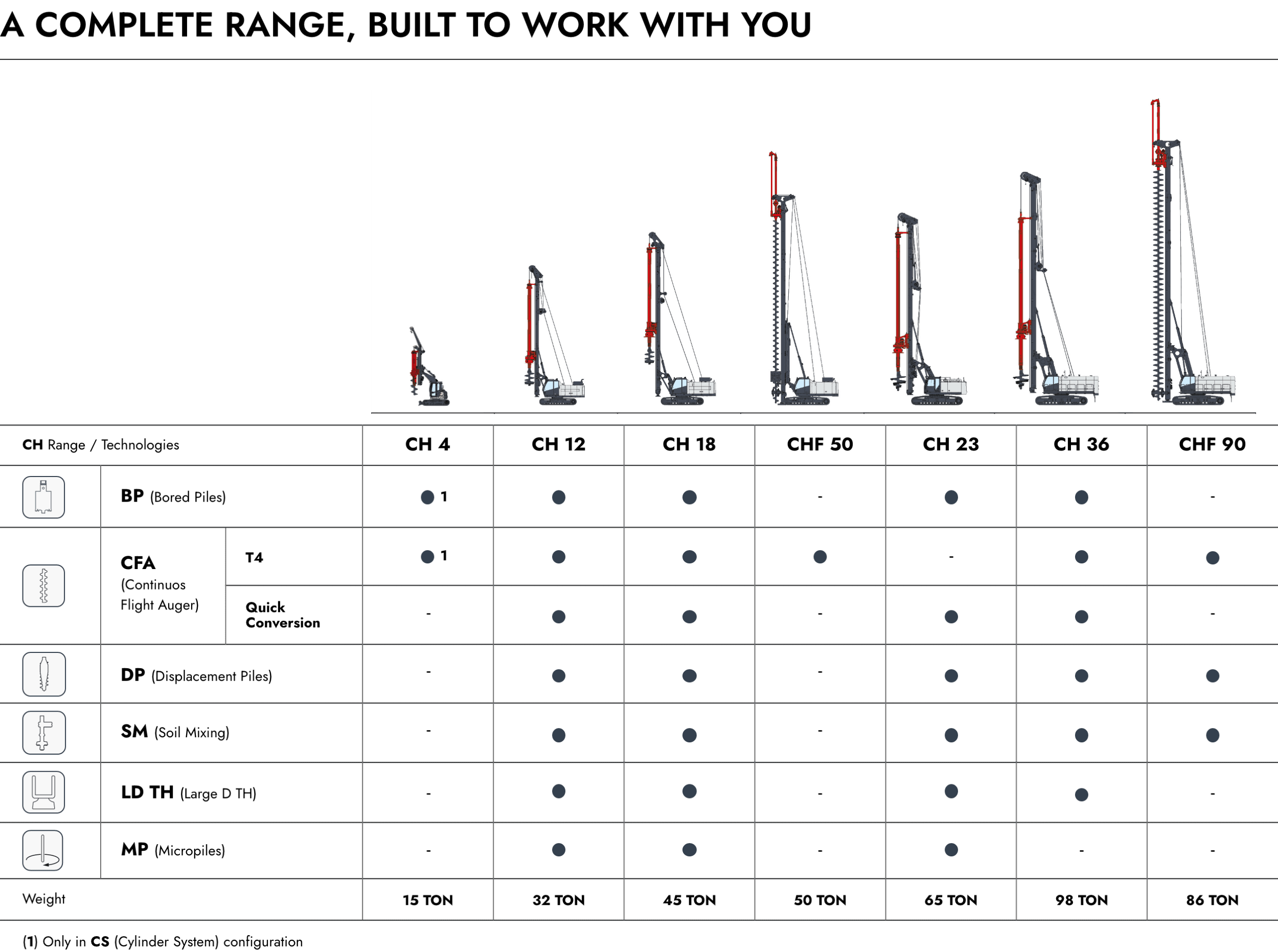

Thanks to their modular design, each rig can be adapted to all major foundation and ground improvement techniques, offering outstanding operational flexibility. In addition to the standard configurations, the CH range includes special versions for the installation of micropiles, large-diameter DTH hammer piles, and vibro stone columns.The range is further complemented by two models dedicated exclusively to CFA piling, in the 50 and 86 ton classes.Comacchio pile rigs are engineered to deliver the optimal balance of efficiency, productivity, ease of transport, and the highest safety standards.

ENERGY EFFICIENCY AND SUSTAINABILITY

CH piling rigs are equipped with latest-generation engines and advanced exhaust after-treatment systems to ensure optimal emission control. The High-Efficiency hydraulic system minimizes energy losses and, combined with intelligent engine and cooling management, optimizes performance while reducing fuel consumption and noise levels. The low-noise rotary head and the overall efficiency of the system further help to lower environmental impact and operating costs.

FLEXIBILITY AND HIGH PRODUCTIVITY

The machines’ modular design, flexible control system, and multi-purpose rotary heads allow each rig to be adapted to all major foundation and ground improvement techniques. The availability of different crowd and pullback systems, rapid conversion kits, and counterweight solutions enables each machine to be tailored to actual jobsite requirements, ensuring high productivity and continuous operation even in the most demanding conditions.

EASY TRANSPORT AND FAST SETUP

Thanks to their compact design and high level of component integration, Comacchio rigs offer reduced mobilization costs and short setup and dismantling times. Automated and assisted setup functions, together with radio remote control for crawler tracks, simplify positioning operations and make transport and jobsite preparation faster, safer, and more efficient.

ERGONOMICS AND SAFETY

The cabin, certified TOPS and FOPS-1, is designed to provide maximum operator protection and comfort. The working environment is fully glazed and features sliding doors, a 360° camera system, LED work lights, and climate control. The human-machine interface, based on the Comacchio Control System (CCS), is intuitive and allows interactive control of all functions, many of which are automatic or assisted. The ComNect fleet management system also enables remote fleet monitoring. High-quality materials, a clean and rational component layout, and safety devices compliant with the most stringent European regulations complete a design focused on reliability, ergonomics, and operator protection.